Steps of Designing a Solar Powered Pumping System

Step one : Determine needed flow.

Flow is the amount of water you need, and how much water you need to irrigate or supply to your animals in one minute or one hour. Think of your needed flow in terms of gallons per hour or gallons per minute.

As an example:

You have 40 sheep and 4 non-lactating cattle grazing where they need water. You’ve found that on a really hot and dry day, the sheep might empty a 40 gallon watering trough that you filled that morning. The cattle empty a 50 gallon trough. That’s 40 + 50 gallons consumed, or 90 gallons in 12 hours. Now consider that on average, a solar panel fixed facing one direction on a hot sunny dry day might only produce power for a pump for six hours. On a partly sunny day maybe only 3 hours. So the same 90 gallons would need to be delivered in six hours or even three. Let’s use the conservative three: 90 gallons delivered in three hours = 30 gallons per hour or 0.5 gallons per minute. The pump will need to pump water so it flows at 0.5 gallons per minute or more.

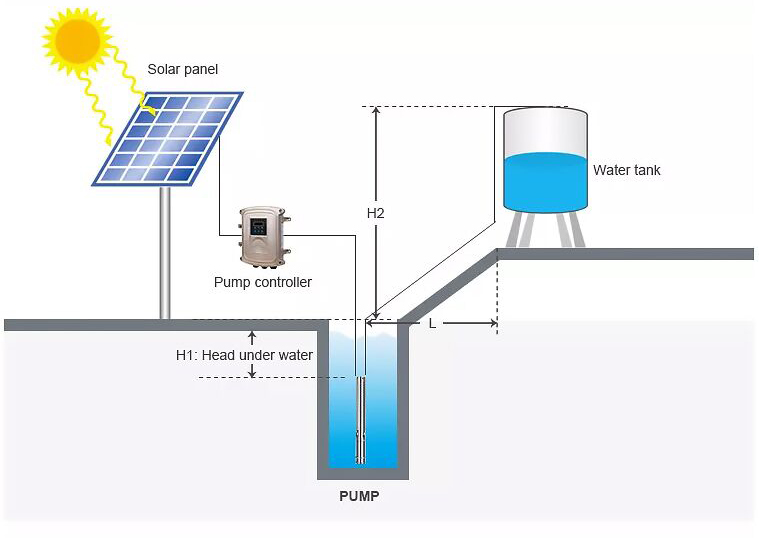

Step Two : Determine how much pressure is needed to get water from source to destination.

Determine this as total pressure in psi (pounds per square inch) or feet of head. Total pressure needed is a combination of:

A) psi to overcome elevation difference (equivalent to 0.433 times the elevation difference in feet between the water level of the source and the discharge at destination).

B) psi needed to force water through any filters, special valves, or irrigation fittings.

C) psi needed to overcome friction loss in piping.

Consult the filter, valve or fitting manufacturers for estimates of psi needed to force water through these components at the desired flow rate. Friction loss through piping depends on how much water flows through the pipe, what type of piping, the length of pipe, number of bends or restrictions and what diameter of piping is used. There are many tables and calculators available online to assist with this determination, such as this useful one. Generally, to avoid the need to overcome the pressure loss due to friction within piping, a larger diameter distribution piping can be used. Typically the largest diameter pipe is used to get water from the pump to the destination, then smaller branches of piping can be used at the destination if needed, say for example, at the final stage of water exiting the system through drip tape or drip emitters in an irrigation system.

Here is an example of determining pressure needed: You want to pump from a spring whose water level is 50 feet below a field where you have watering troughs for livestock. Remember you determined that you need 0.5 GPM for this task above. Your filter will need the pump to produce at least 2 psi to push water through at this rate. You are using a 400 foot run of ¾” polyethylene tubing. Total pressure needed equals:

For the elevation difference: 50 feet difference X 0.433 psi/foot = 21.65 psi.

For the filter and valves: 2 psi (as determined by product literature or consulting with the manufacturers for a specific flow rate)

For the piping: 0.12 psi to get 0.5 gpm water through the 400’ of ¾” piping (determined with online friction loss tables or calculators)

Total psi needed is 21.7 + 2 + 0.12 = 23.8 psi, or roughly 24 psi.

1 psi = 0.433 of feet of head, so to convert psi to feet of head we divide 24 / 0.433, which equals about 55 feet of head (Note that after adding pressure loss from piping and filters, etc., this is more than the original 50 feet elevation difference). Some solar powered water pump specifications are listed in feet of head and some are listed in psi, so it is good to know both.

Step three : Now you are ready to select a pump!

Solar water pumps are rated to produce a certain flow at a certain pressure when supplied a certain amount of power. Now comes the fun part. You will need to reference pump specifications that rate the pump output in terms of pressure and flow. Tables or graphs, commonly known as pump curves, are available from the pump manufacturers or online in product literature.

When referencing the pump specs, first make sure that the pump will provide the amount of pressure you determined is needed. Then move along the table or pump curve graph to determine whether or not the pump will produce the required flow at the needed pressure. That’s it! If flow is not sufficient at the particular pressure you need the pump to produce, then you will need to use a different model or different type of pump.

If you expect to operate the system at various flow rates, you may want to build a system curve as shown above and plot this against the pump curve to determine how the two will interact.

Here is an example evaluating the solar pump. Let’s use the pressure and flow that were determined to be needed in previous examples, above: 55 feet of head and 0.5 gallons per minute were needed

The table on page two of the pump specifications for the solar pump lists what flow the pump will deliver at increments of 20 feet of head. You need at least 55 feet of head, so to be safe, use the 60 feet of heat figure on the table. Then look along the table to determine the flow for the different models of pumps at 60 feet of head. You’ll see that model 1322 produces 0.51 gallons per minute at 60 feet of head– that meets your needs of 0.5 gallons per minute! You can continue to compare other models that will pump the minimum flow you need at 60 feet of head. Oftentimes a different model of the same make of pump will provide more flow at a given pressure, but may require more power supplied to the pump. You can also compare pricing. The main goal at first is to determine what models won’t and will meet your needs.

Step Four : Determining the power needs for the pump at the desired pressure and flow rate

Power required by pumps to deliver a certain amount of pressure and flow is listed in product literature and specifications. Take the above example again. According to the solar pump specs, the model you chose that will deliver 0.51 gallons per minute at 60 feet of head will need a minimum of 36 Watts of PV. You can then shop for panels that are rated at this Wattage or higher. Remember, if you are wiring the panel directly to the pump without batteries, be sure to consider whether or not you need 20% more wattage than listed in the specifications. Product literature will usually make mention of whether or not you need to do this. In the solar pump example here, the specifications already take into account that the solar pv panels will be directly wired, but other spec sheets are different. When in question, consult with technical support at the pump manufacturer.